Contact Me

Contact Me

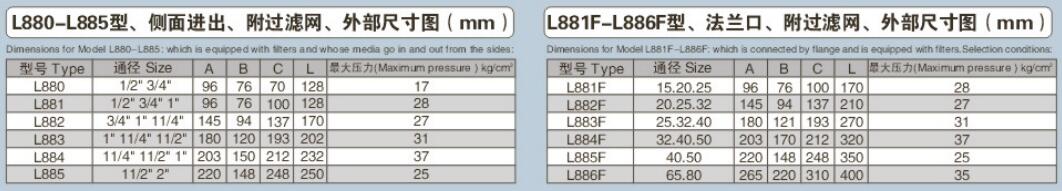

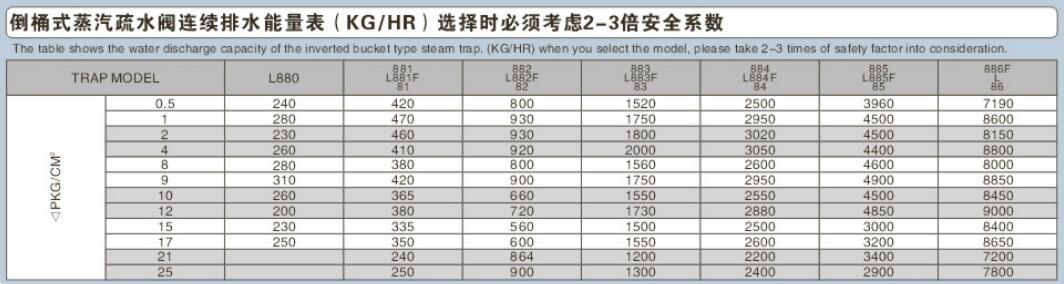

The discharge capacity required for steam trap is determined by the max mum condensation water flow. Which is equal to the maximum gas consumption multiplying by rates (2-3times). It ts required to speedy the maximum differential pressure (that s. upstream pressure subtracts downstream back pressure), maximum working temperature, working conditions. connection. valve materials for steam traps.

Selection Conditions

The discharge capacity required for steam trap is determined by the max mum condensation water flow. Which is equal to the maximum gas consumption multiplying by rates (2-3times). It ts required to speedy the maximum differential pressure (that s. upstream pressure subtracts downstream back pressure), maximum working temperature, working conditions. connection. valve materials for steam traps.

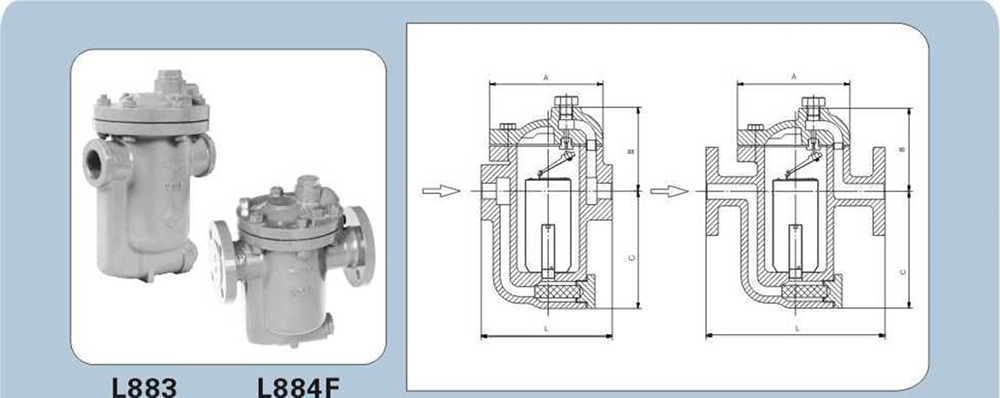

LONZ averted bucket steam trap, as a mechanical steam trap, has outstanding performance and can be applied under low. medium and high pressure. All the internal are made of stainless steel and the seat is applied heal-treated steel. It is firm in structure and resistant to abrasion and corrosion. And it has long life circle and is not perishable. Lt is highly resistant for condensation water recovery system for its characteristics as steam saving capacity, high heat engine efficiency and resistance to back pressure. The steam trap may be assembled will check valve so as to save piping space.

Inserted bucket steam trap works with the principle of density contrast between condensation water and steam. The internal structure is connected to bucket with lever system, working on steam pressure switches. The bucket is a level sensor:in the steam trap with opening downward. When the device starts up. air and low temperature condensation water enter into the tube. At this I me. the steam trap is completely open. which allows quick discharge of air and low temperature condensates water. And the temperature arises soon.When the steam enters into the bucket, it will float up. Since the bucket connects with lever, the lever will drive the valve core to close the valve. The small vent in bucket can drain air automatically. When some of steam ts drained out form the vent and others become condensate. then the bucket will sink lack of float. The lever which is connected to bucket will drive the valve the valve core to open the valve. And then tie steam will enter into the bucket and the valve will close. Lt will all circle r this way and drain water successively.

Welcome to our website. If you have any requests or suggestions,please feel free to email us at lonz@lonzvalve.com or use the following enquiry form. Please allow us to provide you with the best service.

Welcome to our website. If you have any requests or suggestions,please feel free to email us at lonz@lonzvalve.com or use the following enquiry form. Please allow us to provide you with the best service.